INTRODUCING THE SSA CHALLENGE BOARD

The key to the hands-on experience is the specially designed Selective Soldering test vehicle: the SSA Challenge Board—a multi-layer board that emulates many of the most difficult challenges typically seen in today’s selective soldering environment. Contributions from a variety companies and industry professionals were incorporated into the board’s design to ensure that it simulates both common and unique challenges specific to selective soldering.

You will gain valuable insight into understanding how board design, high thermal mass, component limitations and material conflicts can be conquered with programming techniques and the application of fundamental soldering principles. The challenges on the board are broken down into specific sections that can be exercised individually or in combination

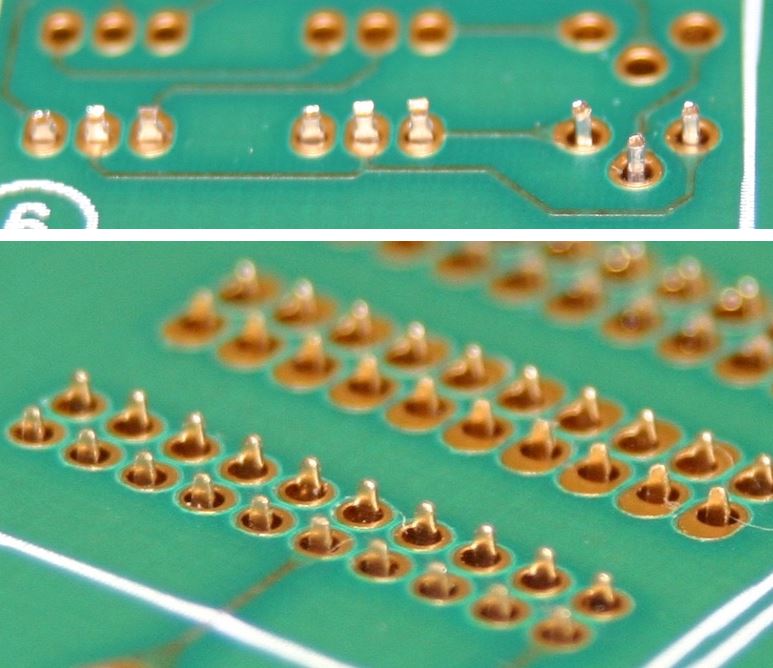

SSA Challenge Board Example Sections 9 & 16

Fine Pitch parts: These sections utilizes varying hole sizes, metal-to-metal spacing, annular ring sizes, lead lengths and staggered pins to teach how to manipulate the basic techniques to eliminate bridging.

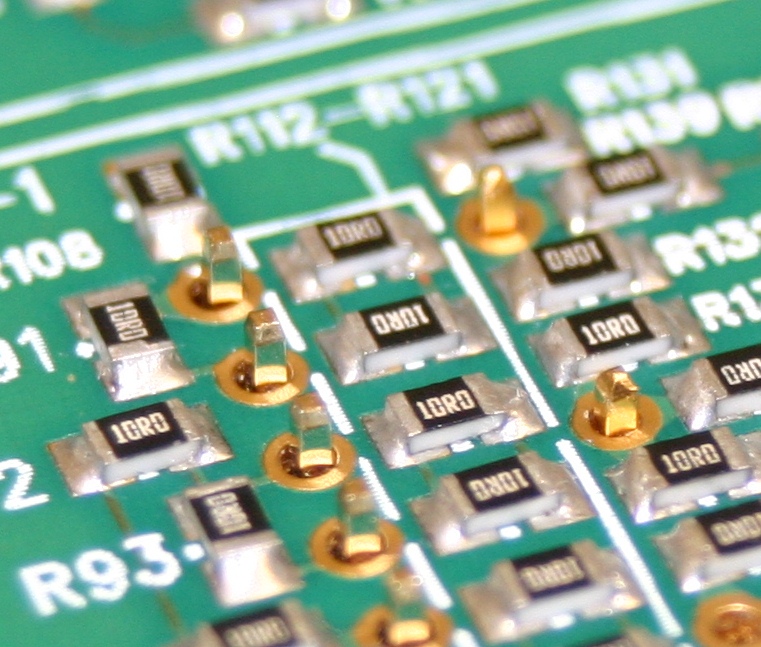

SSA Challenge Board Example Section 5

Tall and/or close SMT Parts: A variety of sections have SMT parts at different heights and proximity to leads being soldered to teach the proper flow control, parameter settings and the proper use of nozzle features to successfully solder in these tight areas without sacrificing speed in more open areas.

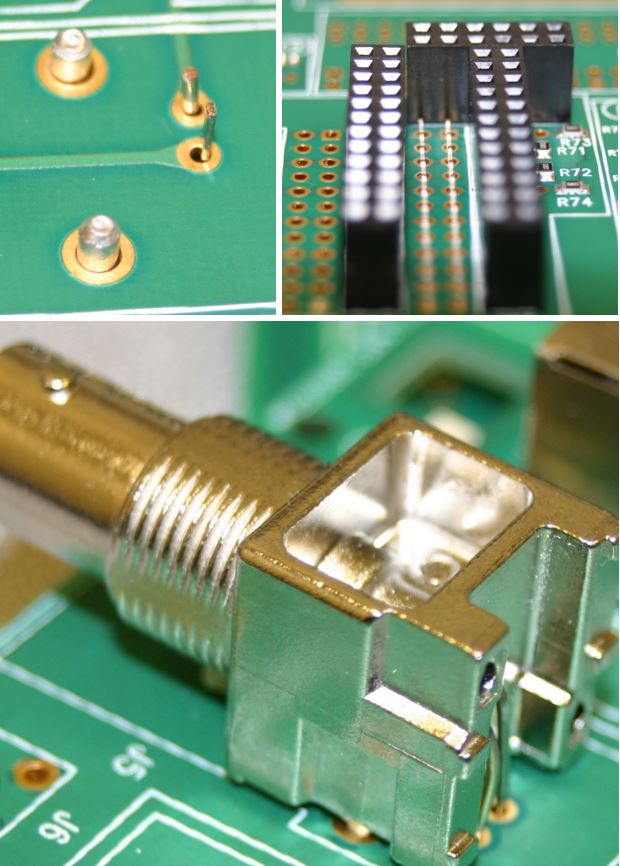

SSA Challenge Board Example Sections 24, 12, etc

A number of other conditions throughout the board provide a variety of challenges, such as, heavily grounded multilayer conditions, known hard-to-solder components, tight lead-to-hole ratios; and tall and close bottom-side components that leave very tight soldering situations.